Mon - Sat 8:00 - 6:30, Sunday - CLOSED

Mon - Sat 8:00 - 6:30, Sunday - CLOSED Mon - Sat 8:00 - 6:30, Sunday - CLOSED

Mon - Sat 8:00 - 6:30, Sunday - CLOSED- Jindal & Hindalco

- Aluminium Sheet & Coil

- Aluminium Products

- Copper Products

- Brass Products

- Titanium Products

- Stainless Steel Angle

- Stainless Steel Bar

- Stainless Steel

- Stainless Steel Checker Plate

- Stainless Steel Perforated Sheet

- Aluminium

- Carbon Steel

- Carbon Steel Chequered Plate

- Carbon Steel Circle

- Alloy Steel

- Duplex Steel

- Special Alloys

- Spring Steel Coil

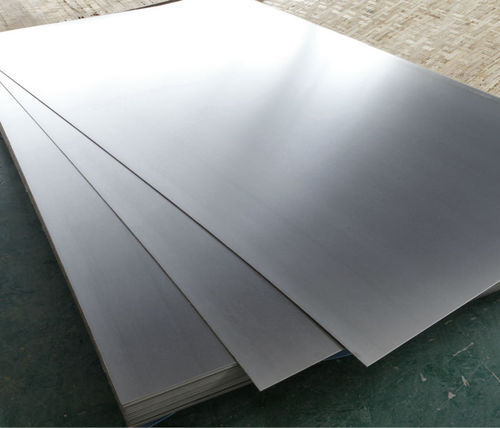

Titanium Sheet

Product Details:

- Tensile Strength 345 880 MPa (Varies by Grade)

- Thickness 0.5 mm to 60 mm (Customizable)

- Thermal Conductivity 17 W/mK at 20C

- Hardness Rockwell B70 - B90 (Depends on Grade)

- Product Type Titanium Sheet

- Types of Alloy Pure Titanium (Commercially Pure) and Titanium Alloys (e.g., Ti-6Al-4V)

- Material Titanium

- Click to view more

Titanium Sheet Price And Quantity

- 2400 INR/Unit

- 1 Kilograms

- ASTM B265, ASME SB265, AMS 4911

- Aerospace, Marine, Chemical Processing, Medical, Industrial

- Cold-Rolled, Hot-Rolled, Polished, Pickled

- 4247 cm at 25C

- Excellent formability and ductility

- Up to 2000 mm (Customizable)

- 0.52 J/gK

- Can be cut, welded, drilled, and machined

- Up to 6000 mm (Customizable)

- 105 GPa

Titanium Sheet Product Specifications

- Grade 2 (Common), available in Grade 1, Grade 5, etc.

- Excellent Corrosion Resistance

- 17 W/mK at 20C

- 0.5 mm to 60 mm (Customizable)

- High Strength-to-Weight Ratio

- 1660C 1670C

- Titanium Sheet

- 4.51 Gram per cubic centimeter(g/cm3)

- 345 880 MPa (Varies by Grade)

- Silver Grey

- Flat Sheet

- Titanium

- Pure Titanium (Commercially Pure) and Titanium Alloys (e.g., Ti-6Al-4V)

- 99.5% Ti (Typical), with trace elements of C, N, H, Fe, O

- Rockwell B70 - B90 (Depends on Grade)

- ASTM B265, ASME SB265, AMS 4911

- Aerospace, Marine, Chemical Processing, Medical, Industrial

- Cold-Rolled, Hot-Rolled, Polished, Pickled

- 4247 cm at 25C

- Excellent formability and ductility

- Up to 2000 mm (Customizable)

- 0.52 J/gK

- Can be cut, welded, drilled, and machined

- Up to 6000 mm (Customizable)

- 105 GPa

Titanium Sheet Trade Information

- 1-2 Days

- Asia, Australia, Central America, North America, South America, Western Europe, Middle East, Africa

- All India

Product Description

A lightweight and strong metal product made from pure titanium or titanium alloys is called titanium sheet. High strength, exceptional corrosion resistance, and biocompatibility are just a few of its standout qualities. Due to their adaptability and special qualities, these sheets are used in a variety of sectors. They support structural integrity and fuel efficiency in aerospace. They are resistant to corrosive substances, which is advantageous for the chemical sector. The biocompatibility of medical implants like plates and screws is used. They are used in marine areas because they resist corrosion. Titanium sheets increase the durability and performance of sporting equipment. Moreover, the visually arresting surfaces of architectural and design projects attract to people. Overall, titanium sheets have a winning mix of advantages for many important applications.

The flat, adaptable metal product known as titanium sheet is known for its remarkable qualities that provide several benefits in a variety of industries. It is constructed of pure titanium or titanium alloys.

Features of Titanium Sheet:

1. Lightweight: Titanium sheets are among the lightest structural materials available, which helps applications carry less weight overall.

2. High Strength: Despite having a low density, titanium sheets are remarkably strong, offering longevity and structural integrity.

3. Titanium's inherent oxide layer provides the sheets with exceptional corrosion resistance, making them perfect for usage in hostile situations.

4. Titanium sheets are easily shaped, moulded, and weldable, enabling customisation and intricate designs.

5. Titanium is biocompatible, making it appropriate for use in surgical instruments and implants.

Benefits of Titanium Sheet:

1. Aerospace: Due to their excellent strength-to-weight ratio and improved performance, titanium sheets are utilised in aircraft components.

2. Chemical Industry: The sheets' resistance to corrosive chemicals makes them useful in chemical processing equipment.

3. Marine: Titanium is useful for marine applications, such as ship hulls and offshore structures, due to its resistance to corrosion.

4. Medical: Titanium sheets are used in medical implants such as screws and plates because they offer long-term biocompatibility and lower the chance of negative reactions.

5. Sporting Goods: Titanium sheets' strength and light weight make them ideal for tennis rackets and bicycle frames, which enhances performance.

6. Architecture and design: Titanium sheets are used for surfaces in architecture, providing distinctive and eye-catching surfaces.

In conclusion, titanium sheets are essential in the aerospace, medical, marine, and several other industries due to its lightweight nature, high strength, resistance to corrosion, and biocompatibility. Their adaptability and unique qualities help them operate better in a variety of applications by enhancing efficiency, lifespan, and performance.

Unmatched Strength-to-Weight Ratio

Titanium sheets deliver remarkable mechanical strength while maintaining a low density of 4.51 g/cm3. This balance is crucial for aerospace and industrial applications where performance and weight savings are key.

Outstanding Corrosion Resistance

Featuring excellent resistance to corrosion by seawater, chemicals, and atmospheric conditions, our titanium sheets ensure durability in marine, chemical processing, and medical environments, reducing maintenance needs over their life cycle.

Customization at Every Step

From thicknesses of 0.5 mm to 60 mm to a choice of width and length, our sheets can be tailored for unique project requirements. Selected grades and surface finishes allow you to meet precise technical specs for any industry.

FAQ's of Titanium Sheet:

Q: How can Titanium Sheets be customized for specific project requirements?

A: Titanium Sheets can be cut, welded, drilled, and machined to your required dimensions, with customizable thickness (0.5 mm to 60 mm), width (up to 2000 mm), and length (up to 6000 mm). Surface finishes such as cold-rolled, hot-rolled, polished, or pickled are available, allowing you to tailor the product for your application's demands.Q: What processes can Titanium Sheets undergo during fabrication?

A: Titanium Sheets offer excellent formability and ductility, making them suitable for cutting, welding, drilling, and precision machining. This ensures easy integration into aerospace, marine, or medical structures, while retaining high strength and corrosion resistance.Q: When is it beneficial to choose a Grade 2 Titanium Sheet for use?

A: Grade 2 Titanium Sheet is commonly preferred for its balance of moderate strength and outstanding corrosion resistance. It is ideal for chemical processing, marine structures, and industrial equipment where exposure to aggressive environments is expected.Q: Where are Titanium Sheets most commonly used?

A: Titanium Sheets find widespread use in aerospace components, marine vessels, chemical processing equipment, medical devices, and various industrial applications due to their high strength, lightweight nature, and resilience to corrosion.Q: What are the advantages of titanium's strength-to-weight ratio in sheet form?

A: Titanium's exceptional strength-to-weight ratio means that structures made from these sheets are both durable and lightweight, which is crucial for aerospace, automotive, and portable medical devices where reducing mass without compromising strength is a priority.Q: How is corrosion resistance achieved in Titanium Sheets?

A: Corrosion resistance in Titanium Sheets is largely due to titanium's strong affinity for oxygen, forming a thin protective oxide layer on the surface. This layer provides long-term protection against acids, seawater, and atmospheric elements, making these sheets suitable for harsh operating environments.Q: What material types and grades of Titanium Sheets are available for export and supply?

A: We offer commercially pure titanium grades like Grade 1 and Grade 2, as well as titanium alloys such as Ti-6Al-4V (Grade 5). These options allow for selection based on specific strength, hardness, and resistance requirements, as per ASTM, ASME, and AMS standards.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+